Klesa

Luvocom® 3F PEEK 9581 NT Filament

Luvocom® 3F PEEK 9581 NT Filament

Couldn't load pickup availability

Luvocom® 3F PEEK 9581 Filament (Polyether Ether Ketone) Filament

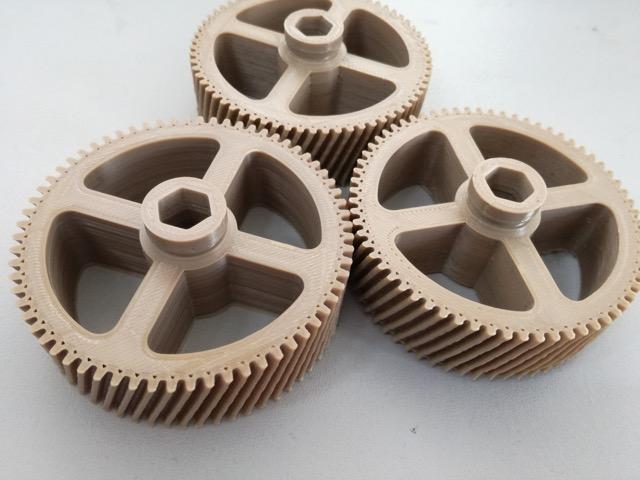

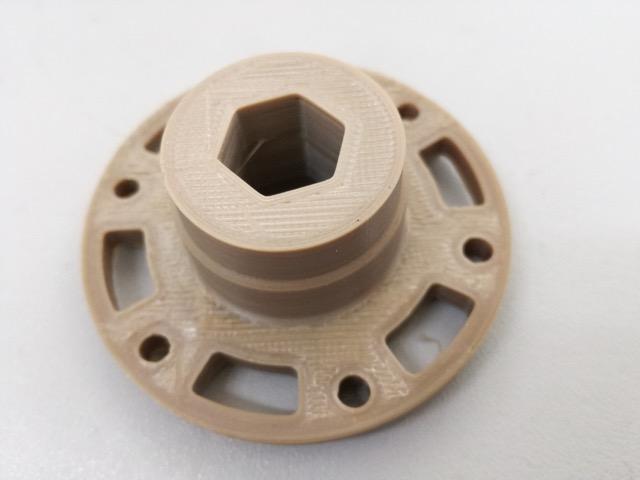

Luvocom® 3F PEEK 9581 is designed to increase flowability and improve printability.

Technical information:

Polyetheretherketone (PEEK) is a semi-crystalline thermoplastic with excellent mechanical and chemical resistance properties that are maintained at high continuous operating temperatures. PEEK is one of the world's most powerful engineering plastics. PEEK is used to manufacture parts in the aerospace, automotive, oil and gas, and pharmaceutical industries. The material is approved in accordance with EN ISO 10993-1, -5 and -12, in accordance with UN-ECE R.118.03 (fire behavior of bus materials) and meets the requirements of NORSOK M 710.

In 3D printing (also called additive manufacturing), PEEK is primarily used to replace polymer and metal components in aircraft, mechanical engineering parts, specialty automotive applications, and custom prosthetics such as cranial implants. Our customers have used our PEEK materials to 3D print: aircraft parts, industrial machinery parts, pump parts, experimental aircraft parts, space industry parts and in research for future medical, aerospace and space applications for the use of PEEK.

Based on customer feedback, PEEK has been a difficult material to 3D print. PEEK requires excellent thermal management in the build chamber during printing. Many high-temperature 3D printers are simply not up to the task, and the learning curve for new users is steep. We have tested most commercially viable grades of PEEK to determine how they perform in terms of printability and mechanical properties of the printed parts. In general, we at 3D4 Makers only manufacture pure materials without additives. In this case, we found that additives could be used in PEEK to improve the flowability and printability of the material and the quality of the manufactured parts. In collaboration with our OEM and industrial partners, we have succeeded in creating Luvocom® 3F PEEK 9581 Filament, the first PEEK filament specifically designed for FDM 3D printing (material compression or FFF).

We hope this material will make it easier for companies to actually manufacture with PEEK. We continue to offer our regular PEEK material along with Luvocom® 3F PEEK 9581.

3D4MAKERS Luvocom® 3F PEEK 9581 Filament has unique properties because it is not in contact with water during the production process and is directly packed in a vacuum-sealed package.

Luvocom 3F PEEK 9581 Filament is especially suitable for use in FDM and FFF-3D printers. The material has excellent adhesion between layers, which significantly improves impact resistance, strength, durability and the printing process.

Dimensions and Tolerance

| Size | Diameter tolerance | Swell |

|---|---|---|

| 1.75mm Filament | +/- 0.05mm | 95% |

| 2.85mm Filament | +/- 0.10mm | 95% |

Physical properties

| Description | Value | Test method |

|---|---|---|

| Density | 1.31 g/cm3 | ISO 1183 |

| Traction module | 3.8 GPa | ISO 527 |

| Tensile strength | 97 MPa | ISO 527 |

| Impact resistance Notched Izod | 7 Kj/m² | ISO1791eA |

Print settings

| Description | Value |

|---|---|

| Printer nozzle temperature | 390 to 440°C |

| The temperature of the heated substrate | 120°C |

| Print speed | 15-30 mm/s |

| Fixing the base | Magigoo HT for glass or PEI board |

| Drying recommendations | 120°C, 2-4 hours |

For best printing results, we recommend keeping the 3D printer in a room with no draft or temperature fluctuations. Keep the 3D printer away from direct sunlight. This room cannot be used as a bedroom.

When the 3D printer is not in use, it is important to store the 3D4MAKERS Luvocom® 3F PEEK 9581 Filament in a bag and in a cool, dry, dark place until it is used again.

Exposure control / Personal protection

Local exhaust ventilation is required at the workplace or in the 3D printer.

Legally required information

1 Certain safety, health and environmental regulations and legislation for the substance or mixture.

Classification of the substance or mixture

The substance is not classified as dangerous according to Regulation (EC) No. 1272/2008 (CLP/GHS) and Directive 67/548/EEC.

2 Chemical safety assessment: Not applicable

RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals).

Recommended Limits

Do not use for medical applications that require permanent implantation into the human body. Luvocom 3F PEEK 9581 Filament produced by 3D4MAKERS meets European RoHS and REACH guidelines.

TDS

You can find the technical data sheet for Luvocom® 3F PEEK 9581 filament here.

MSDS

You can find the material safety information for Luvocom® 3F PEEK 9581 Filament here.

Share