Klesa

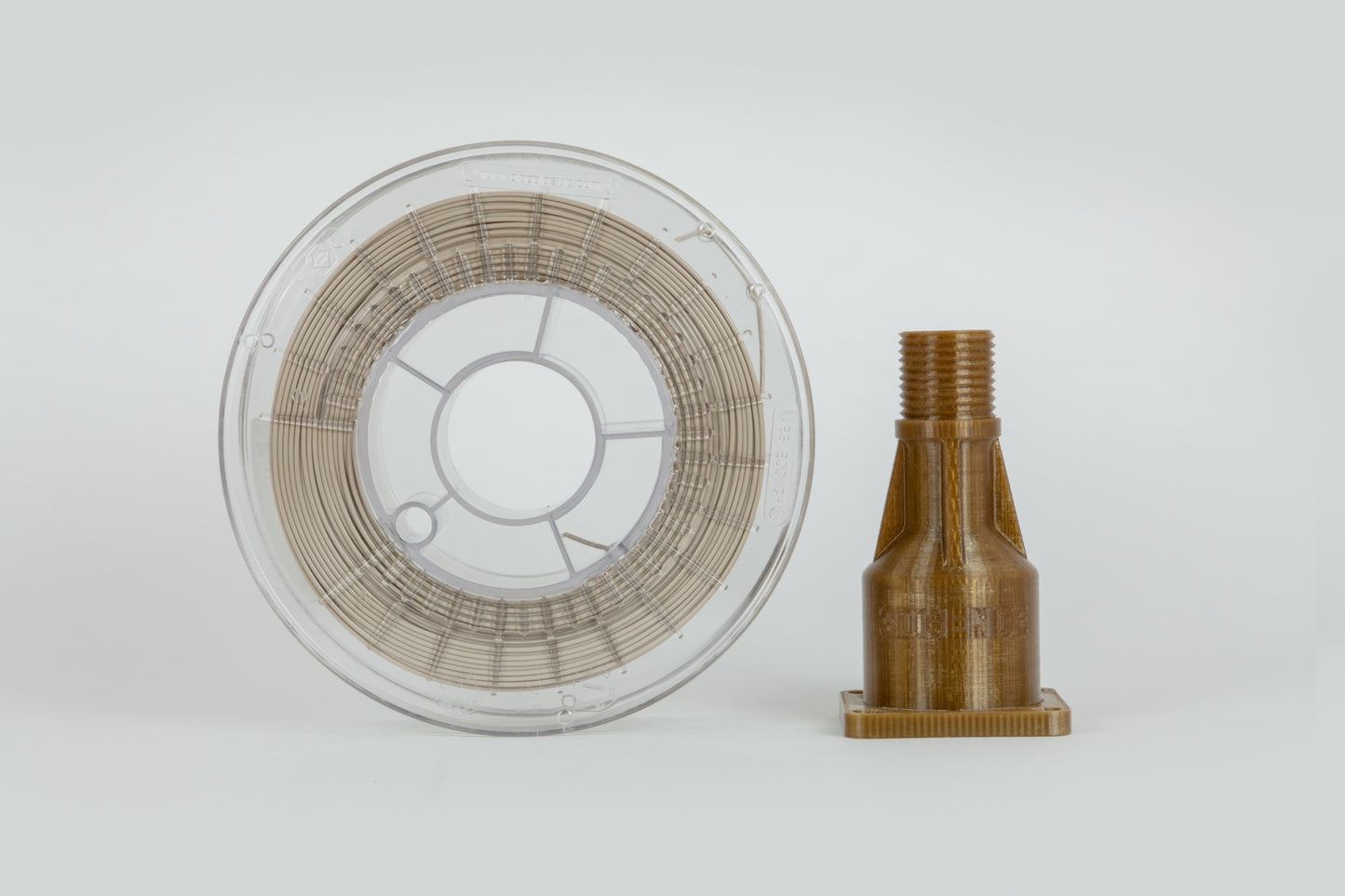

PEEK Filament

PEEK Filament

Couldn't load pickup availability

PEEK (Polyether Ether Ketone) Filament

3D4MAKERS PEEK Filament is delivered vacuum packed in a recyclable box.

Technical information:

Polyether ether ketone (PEEK) PEEK polymers are obtained by phase growth polymerization. PEEK is a semi-crystalline thermoplastic with excellent mechanical and chemical resistance properties that can be maintained at high temperatures. PEEK is considered one of the world's highest performance engineering plastics, along with other polymers in the PAEK family, such as PEKK. PEEK is used to manufacture parts for demanding applications in the aerospace, automotive, oil and gas, and pharmaceutical industries. This PEEK filament is based on VICTREX® PEEK 151G grade.

3D4MAKERS' PEEK filament has unique properties because it is not in contact with water during the production process and is directly vacuum packed. These properties make 3D4MAKERS' PEEK filament particularly suitable for use in FDM and FFF 3D printers. The material has excellent adhesion between layers, which significantly improves impact resistance, strength, durability and the printing process.

The PEEK filament produced by 3D4MAKERS meets the European regulation EC No. 1935/2004, EC No. 2023/2006 and EC No. 10/2011 concerning plastic materials and products in contact with food, and is also FDA (Food and Drug Administration) approved for food contact. The dyes used by 3D4MAKERS to color the filament also meet these European regulations.

Dimensions and Tolerance

| Size | Diameter tolerance | Swell |

|---|---|---|

| 1.75mm Filament | +/- 0.05mm | 95% |

| 2.85mm Filament | +/- 0.10mm | 95% |

Physical properties

| Description | Value | Test method |

|---|---|---|

| Density | 1.26 g/cm³ | ISO 1183 |

| Traction module | 4.1 GPa | ISO 527 |

| Tensile strength | 105 MPa | ISO 527 |

| Impact resistance Notched Izod | 5 Kj/m² | ISO 180/A |

Print settings

| Description | Value |

|---|---|

| Printer nozzle temperature | 370 to 420°C |

| The temperature of the heated substrate | 120°C + |

| Drying recommendations | 120°C, 2-4 hours |

| Print speed | 15-30 mm/s |

| Fixing the base | Magigoo HT for glass or PEI board |

For best printing results, we recommend keeping the 3D printer in a room with no draft or temperature fluctuations. When the 3D printer is not in use, it is important to store the filament in a bag and in a cool, dry, dark place until it is used again.

Also try our Luvocom 3F PEEK 9581 Filament.

Exposure control / Personal protection

Local exhaust ventilation is required at the workplace or in the 3D printer.

Legally required information

1 Certain safety, health and environmental regulations and legislation for the substance or mixture.

Classification of the substance or mixture

The substance is not classified as dangerous according to Regulation (EC) No. 1272/2008 (CLP/GHS) and Directive 67/548/EEC.

2 Chemical safety assessment: Not applicable

RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals).

Recommended Limits

Do not use in medical applications that require permanent implantation into the human body. The PEEK filament produced by 3D4MAKERS meets the European RoHS and REACH guidelines.

TDS

You can find the technical data sheet for PEEK filament here.

MSDS

You can find the material safety information for PEEK Filament here.

Share