Klesa

PI Z2 Filament

PI Z2 Filament

Couldn't load pickup availability

Description

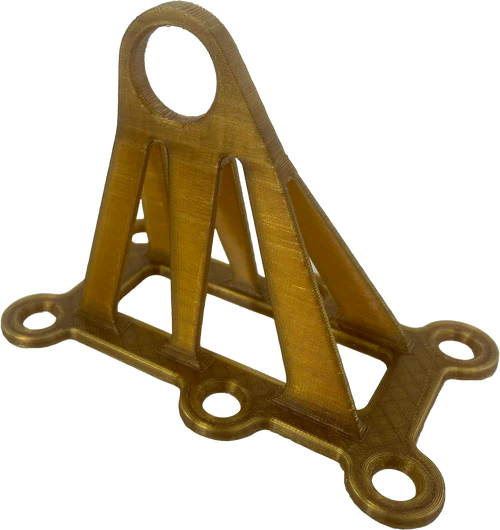

PI Z2 Filament is a printable polyimide. This material has critical advantages for printing parts that require high tensile strength and better yield. In addition, PI filament enables high-performance parts to be printed on a wider range of printers. This material can also lead to higher reliability in part manufacturing processes. In addition, the parts do not need to be hardened after printing in order for them to work well. Polyimide is a very high strength polymer that is inherently flame resistant, with excellent insulating properties and excellent thermal stability. PI filament meets EN 45545, R22 and R23 HL3 requirements and is therefore suitable for railway vehicle applications.

Easy printability means high yield during printing (eg high throughput) with fewer rejected parts. High mechanical strength (including Z-strength) for performance in all directions Low warping helps ground attachment and improves reliability Bio-inspired monomers for adjustable performance and durability EN 45445 (Fire behavior of train materials)

Printer recommendations

| Description | Value |

|---|---|

| Printer nozzle temperature | 390 to 410°C |

| The temperature of the heated substrate | 120 to 160°C |

| Chamber temperature | 80 to 160°C |

| Print speed | 15 to 150 mm/s |

| Platform material | Glass, carbon fiber plate |

| Fixing the base | Magigoo HT, Nano polymer glue, GeckoTec EZ-Hot |

| Pre-drying recommendations | 120°C, >4 hours |

For best printing results, we recommend keeping the 3D printer in a room with no draft or temperature fluctuations. When the 3D printer is not in use, it is important to store the filament in a bag and in a cool, dry, dark place until it is used again.

TDS

You can find the technical datasheet for the PI Z2 filament here.

MSDS

You can find the material safety information for PI Z2 Filament here.

Share